Vertical scraper series

LGCX platform suction bottom discharge scraper centrifuge

2018-10-09 16:49:20 Visit:次

Working principle

LGCX automatic vertical suction bottom discharge scraper centrifuge. Mixed solid and liquid fluids enters centrifuge drum via feed pipe ( at low or medium speed).

acting on the centrifugal position. Liquid-solid mixed fluid intercept the solid phase through the filter to filter out the liquid phase. Centrifuge continues to feed until full. Then stop. Solid cake is rinsed and purified when the process requires. And the rinsing liquid is filtered out meanwhile. Centrifuge further filter until the separation requirements are met.

At low speed. the scraper scrape off most of the solid cake. At the same time the air suction device pulls out the filter cakes to complete a working cycle. Automatic matching of scraper action & airflow suction device through material level detection.

The main feature is no foundation integrated installation. the whole machine can be moved. Fully closed form. Can be fed at very low speed or at medium speed without dripping. Discharge mode is air suction with scraper. Small installation space required. Top automatic discharge. Easy to clean.

Technical parameter

| 项目 | LGCX800 | LGCX1000 | LGCX1250 | LGCX1500 | LGCX1600 |

| 转鼓直径mm | 800 | 1000 | 1250 | 1500 | 1600 |

| 转鼓容积L | 110 | 180 | 400 | 600 | 800 |

| 最大装料限量kg | 150 | 250 | 500 | 750 | 1000 |

| 转鼓转速r/min | 1200-1500 | 1100-1300 | 1000-1200 | 800-900 | 800-900 |

| 分离因数 | 645-1007 | 677-946 | 670-1007 | 537-680 | 573-725 |

| 主电机功率kw | 7.5-11 | 15-18.5 | 22-30 | 37 | 37-45 |

| 液压电机功率kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 主机重量kg | 4500 | 6000 | 7000 | 10000 | 11000 |

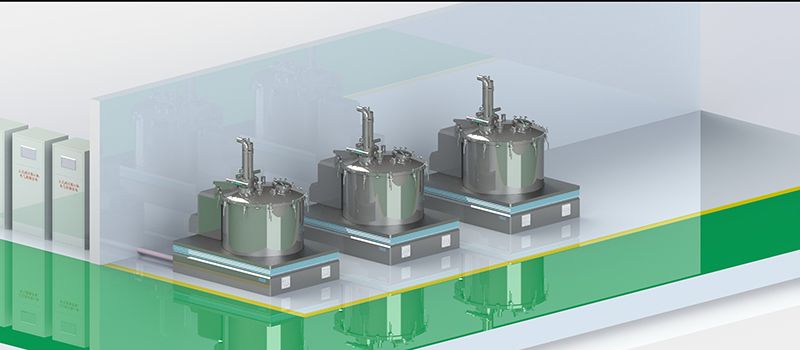

LGCX Form of installation

Main features

flat plate construction. Damping vibration with liquid damping oil. fully enclosed landing without foundation installation. movable

◆ Transmission chamber pressure is lower than main engine pressure. eliminating dust pollution

◆ Large or fully hinged cover form.

◆ Top pneumatic suction device

◆Setting material thickness + Layer detection + N secondary feed. Ensure filter cake thickness

◆ Automatic repair of filter cake imbalance + Over-vibration standby protection

◆Atomization washing. Washing quantitative control. Clearance / pulse washing. . Detection of conductivity of washing filtrate + Liquid output conversion .

◆ High precision drum (machining and balance), high separation factor, improved separation efficiency

◆Set Spindle Seal, scraper Shaft Seal. Axial seal pressure higher than inner cavity 20mbar. Exhaust gas orderly emission

◆ Joint drive belt .Built-in speed sensor

◆External oil supplement (manual/automatic)

◆Digital control stepless layer scraper. Air suction automatic matching. plug rotation automatic repair,

◆Scraper blade wear-resistance and pollution-proof design

◆Fully enclosed hydraulic station, stainless steel oil tank

◆Automatic cleaning program

◆ Fully enclosed system satisfying specification of pharma production

◆ Computer, mobile phone APP remote monitoring system

◆ Multiple layers of protection

Over-vibration protection, cover opening and closing protection

Motor overload protection, Material level protection, scrapper normal position protection. In situ protection of bag pulling support. Process linkage, Mechanical and electrical protection.

N2 protection, Electrostatic grounding protection . Overhaul lock protection .

Fault diagnosis and standby Protection

System configuration

◆Main engine of the centrifuge

◆ Hydraulic system

◆ Pneumatic control system

◆ Electrical control system

◆ Ex-proof operating box / Ex-proof touch screen

◆N2 protection – oxygen content detection

◆N2 protection and N2 replacement

◆Liquid sealing

◆ Air sealing

◆feed valve and washing valve

◆Landing without foundation mounting base

Warning: error_log(/data/home/qxu1194850162/htdocs/en/caches/error_log.php) [function.error-log]: failed to open stream: Permission denied in /data/home/qxu1194850162/htdocs/en/phpcms/libs/functions/global.func.php on line 537

Warning: error_log(/data/home/qxu1194850162/htdocs/en/caches/error_log.php) [function.error-log]: failed to open stream: Permission denied in /data/home/qxu1194850162/htdocs/en/phpcms/libs/functions/global.func.php on line 537

Address:No. 7, Haifeng Road, Nanfeng Economic Development Zone, Zhangjiagang City, Jiangsu Province

Ministry of Foreign Trade:12A, Fugang Building, Zhangjiagang City, Jiangsu Province

Ministry of Internal Trade TEL/FAX :0512-58618029

Technical marketing hotline:15895699718

wab:http://www.tzfilter.com http://www.tzfilter.cn/

Service Hotline:18962211179

E-mail:tz@tzfilter.com

Copyright © 2018 Jiangsu Tongze Filtration Technology Co., Ltd. All Rights Reserved 苏ICP备18055215号-1