Horizontal scraper series

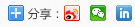

GKH horizontal discharge siphon scraper centrifuge

2018-10-12 14:29:50 Visit:次

The solid and liquid mixture will be fed into the centrifuge drum via feed pipe and distributed evenly all over the inner wall of the drum, at where the solid phase will be retained by filter disk under effect of centrifuge field while liquid phase discharged out of the filtration process. The feeding process will keep going on until the centrifuge drum is fully charged. Filtering cake will be rinsed and purified as necessary and rinsing water will be discharged meanwhile. Then, there comes a further dehydration process till effective separation is achieved. In process of full or moderate speed running, the scrapper will peel off most of the filtering cake and one entire working cycle completed.

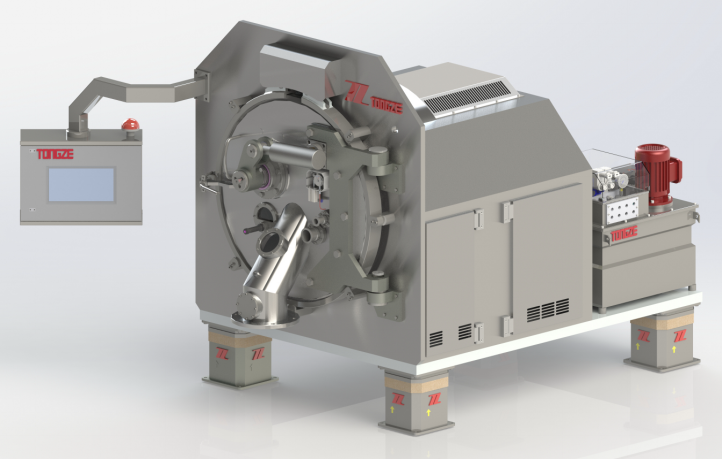

Control process

Whole system elevated and installed: space reserved at same level for discharge and filtering cake conveyance

Main feature

|

机型 |

GKF |

GKH |

GK |

|

开盖形式 |

标准:全开盖 |

标准:平开盖;定制:全翻盖 |

标准:平开盖 |

|

残余滤饼清除装置 |

标配:气体反吹 定制:螺旋滚刀 |

定配:螺旋滚刀 |

定制:气体反吹、螺旋滚刀 |

|

防爆配置 |

定制:置换+氧测+气封+液封+蝶阀 |

||

|

转速 |

按技术参数 |

按技术参数 |

按技术参数 |

|

在线清洗 |

标准:内腔全位置 |

定制:按需求 |

定制:按需求 |

|

在线灭菌 |

定制:有 |

无 |

无 |

|

安装形式 |

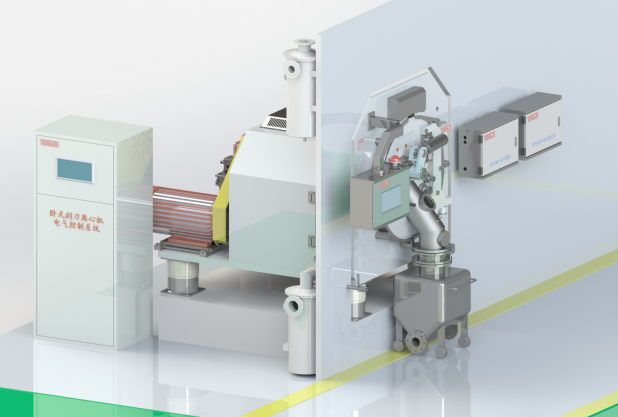

穿墙安装、整机安装 |

||

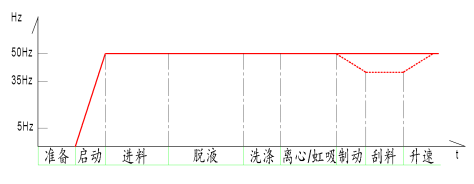

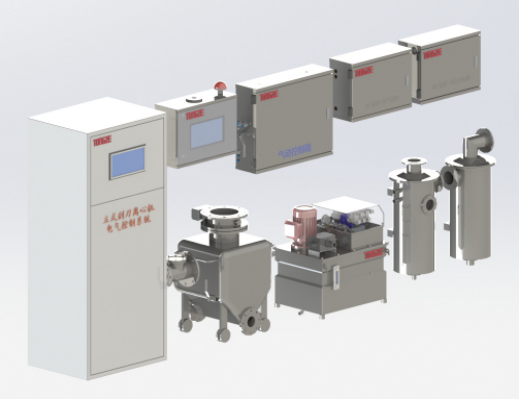

System configuration

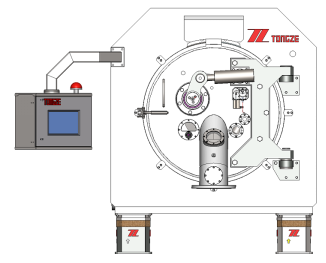

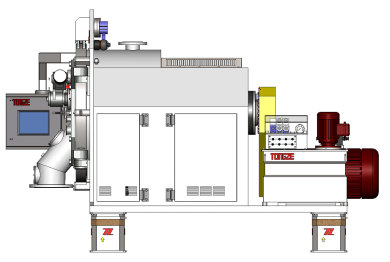

GKH Outline drawing

| 项目 | GK/GKH800 | GK/GKH1000 | GK/GKH250 | GK/GKH1600 |

| 转鼓直径mm | 800 | 1000 | 1250 | 1600 |

| 转鼓容积L | 100 | 180 | 350 | 700 |

| 最大装料限量kg | 125 | 250 | 450 | 950 |

| 转鼓转速r/min | 1600 | 1400 | 1200 | 950 |

| 分离因数 | 1145 | 1097 | 1007 | 808 |

| 主电机功率kw | 30/45 | 37/55 | 55/90 | 90/132 |

| 液压电机功率kw | 1.5 | 1.5 | 1.5 | 1.5 |

| 主机重量kg | 5000/5500 | 6000/6500 | 8000/8500 | 16000/17000 |

Warning: error_log(/data/home/qxu1194850162/htdocs/en/caches/error_log.php) [function.error-log]: failed to open stream: Permission denied in /data/home/qxu1194850162/htdocs/en/phpcms/libs/functions/global.func.php on line 537

Warning: error_log(/data/home/qxu1194850162/htdocs/en/caches/error_log.php) [function.error-log]: failed to open stream: Permission denied in /data/home/qxu1194850162/htdocs/en/phpcms/libs/functions/global.func.php on line 537

Address:No. 7, Haifeng Road, Nanfeng Economic Development Zone, Zhangjiagang City, Jiangsu Province

Ministry of Foreign Trade:12A, Fugang Building, Zhangjiagang City, Jiangsu Province

Ministry of Internal Trade TEL/FAX :0512-58618029

Technical marketing hotline:15895699718

wab:http://www.tzfilter.com http://www.tzfilter.cn/

Service Hotline:18962211179

E-mail:tz@tzfilter.com

Copyright © 2018 Jiangsu Tongze Filtration Technology Co., Ltd. All Rights Reserved 苏ICP备18055215号-1